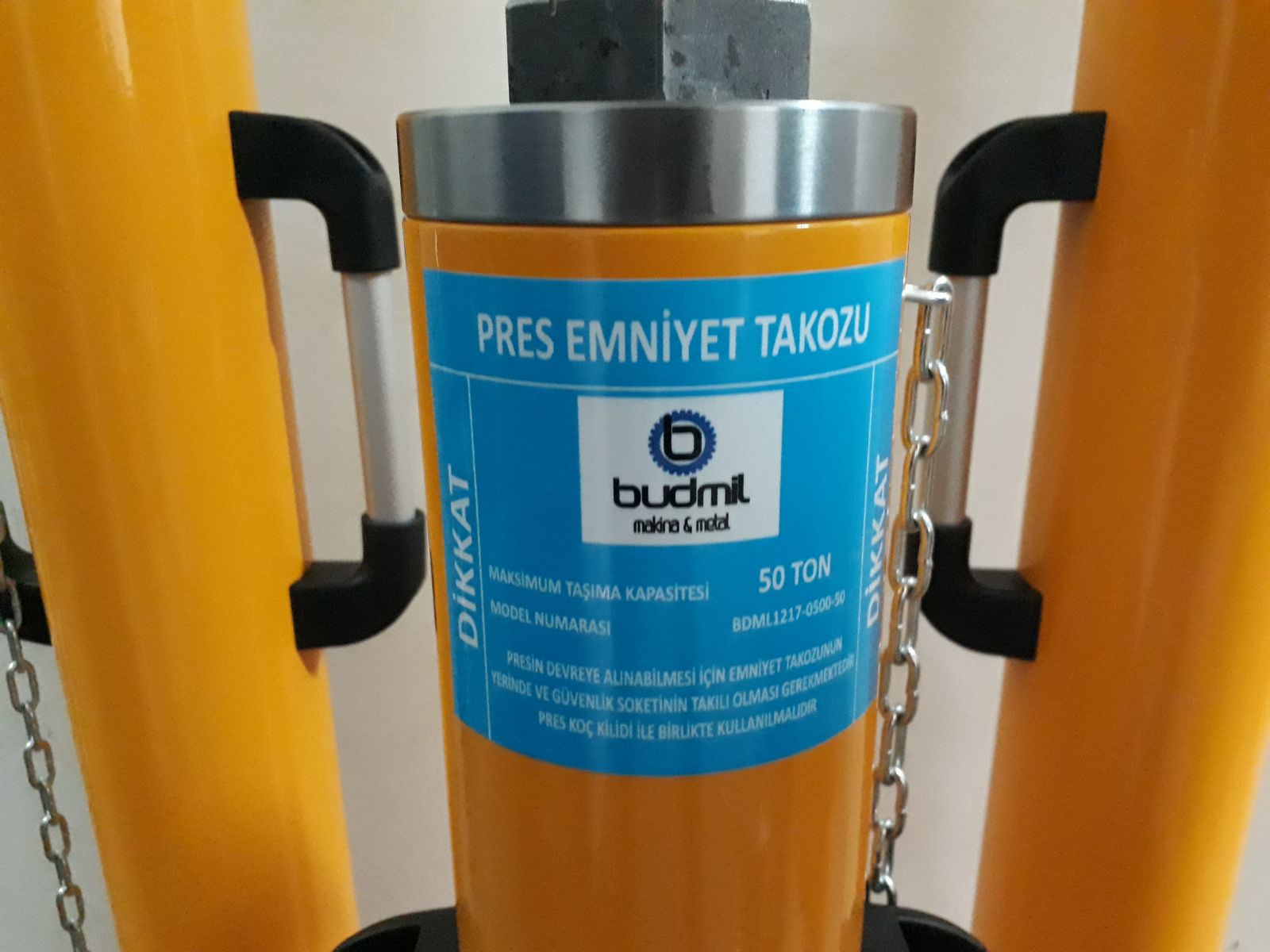

Press safety blocks are equipment used to secure the free weight of the upper ram during mold and press maintenance activities, aiming to eliminate potential risks of accidents. Thanks to their aluminum body, they are much lighter and more ergonomic than steel safety blocks, providing ease of use.

According to Article 180 of the Occupational Health and Safety Regulation; before connecting the mold in motorized presses, the motor will be stopped, and in hydraulic and pneumatic presses with remote control, the pressure connection will be cut off before connecting the mold, and blocks with sufficient strength will be placed between the press head and the table.